Why and where should you use power chuck?

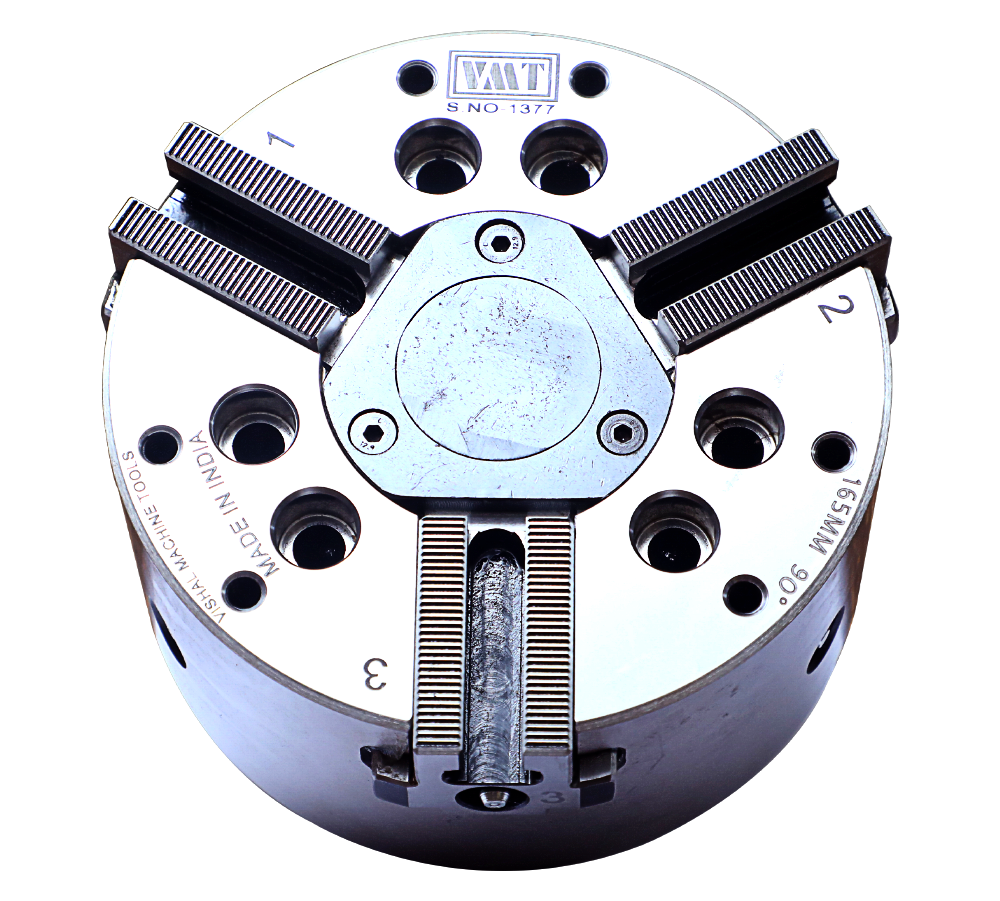

The workpiece is held

firmly in place by the power chuck's jaws (usually 3 or 4 jaws). The term stems

from the fact that an automated power source generates the clamping force

(electrical, mechanical, or other means). There are several benefits to using a

work-holding method tailored to cylindrical objects with radial symmetry.

Advantages

The effectiveness of a

power chuck is unquestionably its most significant benefit. The Hydraulic chuck can now

be clamped at a significantly faster rate thanks to the design, making it

suitable for use in mass production. For high-volume manufacturing, manual

clamping methods are prohibitively time-consuming. As a result, power chucks

are the way to go when productivity is paramount.

Power chucks are used

in several modern machining techniques, such as drilling, milling, turning,

clamping the workpieces, and holding the machine's tools. The following

paragraphs will examine the role of power chucks in those three operations.

Drill bits, milling

cutters, and other cutting tools can be securely held in a power chuck while

the chuck supports the workpiece. To hold a long (or enormous) workpiece

steady, a chuck is mounted on the tailstock of a turning lathe, as shown. Suppose

you're using the chuck to hold a workpiece still while drilling or milling; it

won't rotate. When a cutting tool, such as a drill bit or milling cutter, is

clamped, the spindle causes the tool to spin, allowing it to do its work.

Turning

The power chuck used

for lathe turning is installed on the spindle of the lathe's headstock. In

addition to sharing standard processing capabilities, workpiece-spinning

devices and tool-spinning machines are also functionally comparable. For

instance, the clamping mechanism of a lathe is carried out by the power chuck

and cylinder system; how these parts are assembled affects the lathe's output

accuracy.

Turning machines have a long and illustrious history, dating back thousands of years and placing them among the very first machine tools ever created. There are two primary categories of lathes, distinguished by the method by which the workpiece is held.

Comments

Post a Comment